OxiMax Electrochlorination Systems – Onsite Chlorine generation

We at HES Water Engineers India Pvt. Ltd. are a leading manufacturer of Electrochlorination Systems in India with 2000+ installations since 2005. Our team has 25 years of experience in Electrochlorination, which is a proven technology and science that produces liquid Sodium Hypochlorite by electrolysis of common salt and water. The liquid sodium hypochlorite is of 0.5% to 0.8% strength, thereby making the water safe for human use.

We focus on advanced and sustainable water treatment technology to provide environmental-friendly solutions with an emphasis on offering high-grade equipment for water disinfection, biofouling control, and filtration. By using Electrochlorination as the base technology, our water disinfection and biofouling control systems ensure a continuous supply of safe and potable water while ensuring long-term plant operation.

Our experience combined with our long-standing expertise in managing various disinfection projects has made us a specialist in our field. We manufacture and supply units that are tailored to suit the client’s unique specifications & applications while complying with the industry standards. Also, our Electrochlorination Systems are based on proven technologies that ensure increased safety and reliability at a cost-effective price range. We can supply Batch systems as well as fully Continuous systems (based on PLC or Relay).

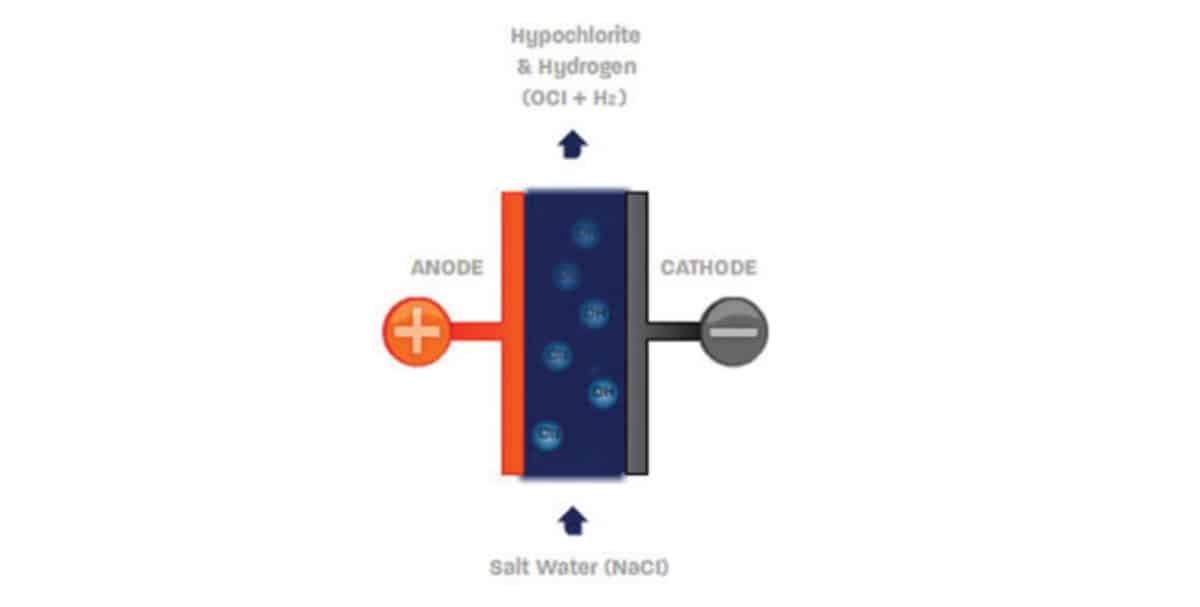

Electrochlorination is the process of applying an electrical current to salt water to produce dilute sodium hypochlorite (bleach) and hydrogen gas. The resultant sodium hypochlorite solution contains between 0.5%-0.8% chlorine. This low concentration is considered non-hazardous to humans yet still destroys viruses, bacteria, and other harmful microorganisms present in the water, making it safe to drink and preventing the spread of diseases.

Unlike other chlorination methods, such as chlorine gas or commercial hypochlorite solutions, electrochlorination doesn’t generate any toxic by-products, nor does it require staff to handle hazardous chemicals, such as chlorine or sodium hypochlorite in high concentrations. The only by-product is hydrogen gas and there are processes to manage and disperse this safely.

Electrochlorination is therefore a highly effective and economical technique for disinfecting water. Unsurprisingly, it’s used all over the world and at all scales. Electrochlorination produces sodium hypochlorite on site on an “as needed” basis. Here at HES Water Engineers, we install electrochlorination apparatus ranging in dosing capacity from 5 grams per hour right up to 10 kilograms per hour for salt based systems and much higher capacities for seawater based systems.

The Process of Electrochlorination Systems

In the Electrochlorination (salt chlorination) process, common salt (Sodium Chloride) is converted to a low strength (0.5% to 0.8%) hypochlorous acid and sodium hypochlorite by electrolysis.

- The process starts with streaming the saltwater through an electrolyzer channel (cathode and anode).

- Next, a low voltage current is applied which leads to electrolysis that results in the production of sodium hypochlorite and hydrogen gas (H2).

- This solution then travels to the tank, wherein the Sodium Hypochlorite is stored and dosed using dosing pumps.

The actual reactions are quite complex. However, the below equation represents the key Electrochlorination reaction:

NaCl + H2O + ENERGY → NaOCl + H2

Benefits of Electrochlorinator Systems

- The process starts with streaming the saltwater through an electrolyzer channel (cathode and anode).The Electrochlorination system can be either batch or automated, as per your requirement.

- It offers easy operation and is user-friendly.

- It is a proven technology for sodium hypochlorite production.

- There is no wastage or harmful byproducts, which makes it environment-friendly.

- It is reliable and provides greater safety as you don’t need to handle any hazardous chemicals.

- It eliminates the dependency on outside suppliers as you can produce your own sodium hypochlorite on-site.

- The initial investment is economical, and it has a low operating & maintenance cost.

Application and Uses of Electrochlorination Systems

- Disinfection of Drinking Water

- Piped Water Supply Schemes under Jal Jeevan Mission

- Biological Wastewater Treatment

- Groundwater Remediation

- Dairy and Food Industry Raw Water Treatment

- Process Water Disinfection

- Industrial Wastewater Treatment and Disinfection

- Swimming Pool Chlorination

Different Models of OxiMax Electrochlorination Systems

1. Brine Water Electrochlorination Systems

1.1 OxiMax MM Series: Continuous-Batch Process Electrochlorinators

OxiMax MM series Electrochlorination System is a patented, advanced technology that helps produce the disinfectant Sodium Hypochlorite from salt and water (brine). It is an ‘Onsite Hypochlorite Generator’ ideal for different water treatment applications.

The major components of the MM series Electrochlorination System are:

- Brine Pump

- Salt Saturator

- Electrolyser Cell

- Microprocessor-based control system

- Power supply

- Hypochlorite storage tank

The MM Electrolyser Cells, in particular, is a patented technology that has computer optimised waterways. It also consists of self-cleaning, high-performance, and long life SCRP electrodes.

OxiMax MM series Electrochlorination models are compact, reliable and offer high efficiency. They are designed to run seamlessly with limited human operator intervention. The MM series Electrochlorination models are available with different outputs ranging from 5-3000 gms/hr.

Benefits of the MM Series Onsite Hypochlorite Generators

- It is suitable for remote locations.

- It has low maintenance & operating cost and offers enhanced safety.

- The long-life electrodes ensure hassle-free service for years.

- It offers optimum electrical & hydraulic efficiency and produces no harmful chemical or byproducts.

- It produces on-demand, on-site liquid sodium (Hypochlorite) that allows for accurate dosing control.

- Since only common salt needs to be transported to the site, you can easily store several months of supply on the site without the worry of degradation.

OxiMax MM Series Applications

- Rural and Urban water supply schemes

- Piped water supply schemes under Jal Jeevan Mission

- Groundwater

- Railway stations

- Power plants & Refineries

- Waste and Sewage treatment

- Swimming pools and Hospitals

- Disinfection of potable water and wastewater up to 6 Ml/day

- Disinfection of potable water and wastewater up to 6 Ml/day

- Disinfection of water in tanks, dams and cooling towers

1.2 OxiMax MMb Series: Batch Model Electrochlorinators

OxiMax MMb Series is a batch model Electrochlorinator system with advanced features and modular design. They are designed to generate 0.5%-0.8% liquid Sodium Hypochlorite in a batch of 4 or 8 hours and are well-suited for locations where a very low capacity of water needs to be disinfected.

OxiMax MMb Series Applications

- OxiMax MMb Series Applications

- Piped water supply schemes under Jal Jeevan Mission

- Zilla Parishad and Panchayati Raj

- Swimming pools and Hospitals

OxiMax Batch-type hypochlorite generators are also available in the Solar Power variant. These are easy-to-operate, and the disinfectant generated by this system can be directly injected into water or wastewater to disinfect 50,000 to 5,000,000 litres of water per day, depending on the system size and level of contamination.

1.3 OxiMax MA Series: Batch Model Electrochlorinators

Designed to produce Sodium Hypochlorite (NaOCl) from salt and water (brine), OxiMax MA Series Electrochlorinators are fully-automated and come with PLC and touchscreen control. They can be used either with ‘softner’ or ‘vacuum’ salt (NaCl) and since the only material required is salt, the MA Series machine helps eliminate the safety, handling and transport issues of using Cl2 gas or bulk hypochlorite.

Also, for maximum energy-efficiency and NaOCl production, these heavy-duty & high-performance cells use an injection moulded PVC casing with a bipolar electrode arrangement.

A typical system of OxiMax MA Series consists of some or all of the following:

- Brine Pump(s)

- Water Softener(s)

- Salt Saturators(s)

- DC Rectifier(s)

- OxiMax MA Series Electrochlorination Cell(s)

- Control System(PLC/HMI)

- H2 Blowers

- Degassing and Storage Tank(s)

- Dosing Pump(s) and/or Venturi Dosing System

- Chiller(s)

- Instrumentation

Benefits of the OxiMax MA Series Electrochlorinators

- It is cost-effective, reliable and skid mounted for easy installation.

- Every Anode and Cathode is visible, and it comes with SC12 MMO coatings on anodes for increased efficiency.

- It is fully insulated (no exposed DC busbars or electrical connections), thereby offering greater personnel safety.

- It comes with a modular configuration and can be fully automatic using PLC or Relay-based control systems.

- Forced air hydrogen gas dilution and purging.

- It offers constant Hypochlorite strength & quality and you don’t require to store/transport any hazardous chemicals.

- It provides easy cell removal, integral voltage monitoring, and has a low maintenance cost.

OxiMax MA Series Applications

- Power Plants

- Refineries

- Steel Plant and Inland Industrial Plants

- Drinking water treatment Plants

- Water and Wastewater Treatment Plants

- Water Theme Parks

- Large Swimming Pools

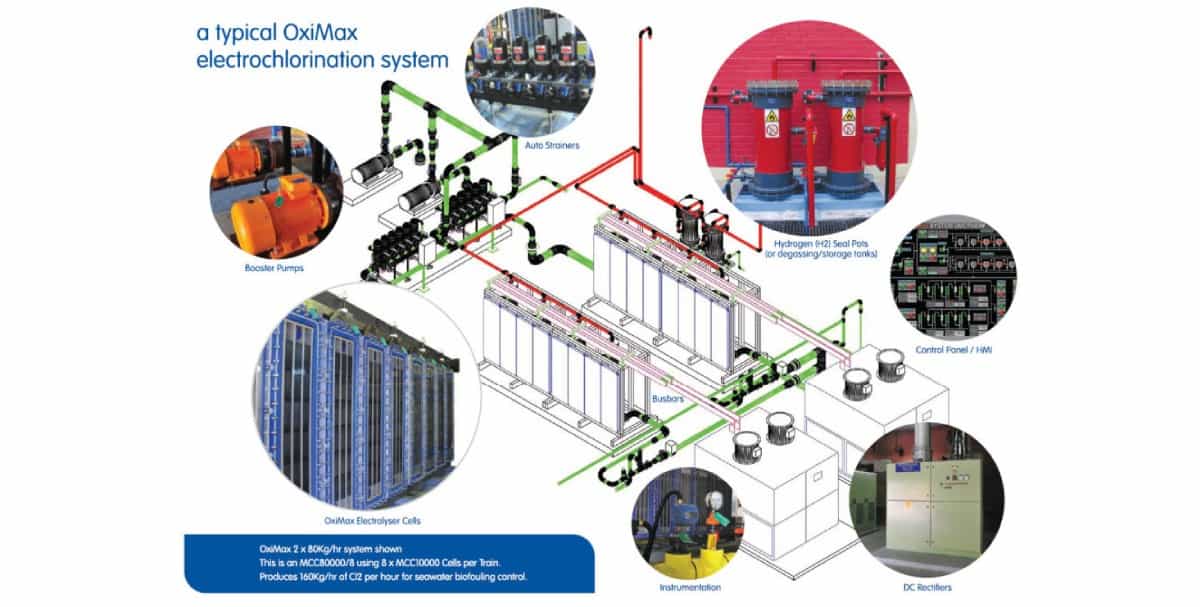

2. Sea Water Electrochlorination Systems

2.1 OxiMax MC Series – Sea Water Based Electrochlorination Systems

The MC Series Electrochlorination Systems are designed to produce Sodium Hypochlorite (NaOCI) from seawater. These heavy-duty, high-performance cells use an injection moulded PVC casing and a bipolar electrode arrangement for greater energy efficiency and NaOCI production.

A typical OxiMax MC Series system consists of some or all of the following:

- Seawater Booster Pump(s)

- Seawater Auto Strainer(s)

- DC Rectifier(s)

- Forced Hydrogen separation

- Shock Dosing Pump(s)

- Hydrogen Blowers

- Degassing and Storage Tank(s)

- Control System (PLC/HMI)

- OxiMax MC Series Electrochlorination Cell(s)

- Instrumentation

Benefits of the OxiMax MC Series Sea Water Electrochlorinators

- This system is completely automatic and can be manufactured or customised for Hypochlorite output of up to 400 kg/hr.

- Every Anode and Cathode is visible, and it offers complete biofouling control.

- For greater personnel safety, it is fully insulated – no exposed DC busbars or electrical connections.

- It has a modular configuration and is cost-effective, safe, reliable and robust.

- Its high-flow velocity waterways help reduce energy consumption and minimise the need for acid cleaning.

- Its high efficiency ensures lower operating cost as well as low maintenance.

- With SC12 MMO Coatings on Anodes and staged hydrogen removal, it offers increased efficiency.

- It comes with integral voltage monitoring and provides easy cell removal.

- Forced air hydrogen gas dilution and purging.

OxiMax MC Series Applications

Power Stations located next to the sea are the ideal application for this Electrochlorination system.

Before using seawater for cooling in the condensers of thermal power stations, disinfection of the seawater is required to control marine growth and prevent biofouling from molluscs, mussels, slime and algae.

Also, for the production of Sodium Hypochlorite, raw materials (seawater and power) are readily available, wherein, the seawater is free, so the only cost is the power used.