Daiki-Axis Johkasou Sewage Treatment Plant

To help save water and the environment, we at HES Water Engineers India in collaboration with Daiki-Axis offers technologically superior sewage treatment plants. Daiki-Axis is a renowned manufacturer of packaged STP systems in India and Asia. As a business partner of Daiki-Axis India, we offer decentralised Packaged Sewage Treatment Plants (Johkasou), which is a technology and concept certified by the Government of Japan and the Ministry of Jal Shakti, Government of India. It has also been certified as a Green Product with the “GreenPro Ecolabel” by CII.

The primary concept of Johkasou-STP is ‘Treat at the site, Reuse at the site’, which is most suitable for Indian conditions and statutory norms.

We offer Sewage Treatment Plants in different sizes 1 KLD to 300 KLD as per your requirements. Our STP can be installed above and/or underground in individual houses, apartment complexes, commercial buildings etc. They also provide greater savings through low maintenance and running cost. Plus, the treated water can be used for various non-portable purposes like gardening, flushing, cooling towers etc.

Johkasou Sewage Treatment Plant

‘Johkasou’ in the Japanese language means ‘purification tank.’ Daiki-Axis Japanese Packaged STPs (Johkasou) are made from 100% FRP and provide a combination of aerobic & anaerobic treatment for sewage at a single shot; with the entire treatment housed in a single FRP capsule. This combined purification structure is capable of treating both night soil (black water) and domestic wastewater (greywater). These STPs can also be customised to suit special use, local compliance, and other requirements.

These ready-to-install STPs deliver exceptional performance while adhering to the global discharged norms. They are well-suited for various government, residential, industrial, and commercial establishments. Also, compared to conventional sewage treatment plants, it offers 50% energy-saving which helps save money.

These high-quality products are based on the principles of modern technologies and management systems. They also undergo stringent and structured quality testing processes during the designing and manufacturing stage for various physical integrity and performance parameters.

Johkasou STPs come in modular construction, which ensures that they can be installed in open spaces. They offer robust performance, scalability and comes with rapid deployment capability. It also has a low cost of ownership and is designed to meet the various standards for treated water discharge applicable around the globe. The best part, with the help of our specially trained sales team and sales partners, we can help you configure these products as per your requirements.

Johkasou STP Treatment Process

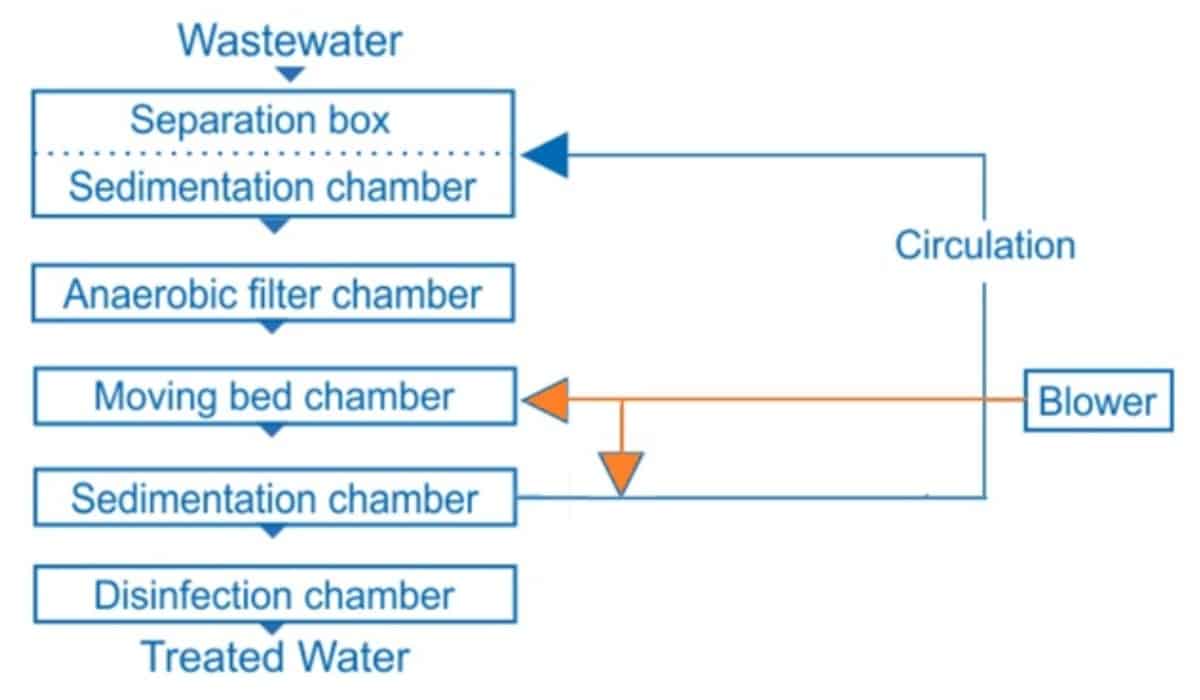

This single tank structure is a compact system that consists of simple treatment processes. The only electrical component in Johkasou STP is the Air blower, and the treatment process includes:

- Separation Box and Sedimentation Chamber: Here the wastewater – solids and floating materials – is collected and separated based on their gravity.

- Anaerobic Filter Chamber: The wastewater – which contains organic material – flows into the Anaerobic Media contact chamber where it is decomposed by anaerobic microorganisms.

- Moving Bed Chamber: The wastewater from the Anaerobic chamber flows into a moving bed (MBBR) chamber wherein the organic waste is further simplified.

- Sedimentation Chamber: The settled sludge from the biological process in the moving bed (MBBR) chamber is placed here. This Settled sludge is then transferred to the sedimentation and separation chamber.

- Disinfection Chamber: Here the waste is further processed and disinfected before being released into the environment or sent for further treatment if need be.

- Inbuilt Circulation Line: The airlift mechanism is adopted for continuous recirculation from the 2nd sedimentation chamber to the separation and sedimentation chamber. This helps facilitate the denitrification process while ensuring that continuous water flows inside the system offering multiple treatments.

Benefits of Johkasou Sewage Treatment Plant

- Johkasua offers a high treatment performance and long plant life.

- It is easy to install, highly modular, and scalable.

- It is 100% leak-proof and non-corrosive.

- It requires minimal maintenance and repair with desludging every six months and monthly removal of plastics.

- It consumes less energy, which ensures low carbon footprints./li>

- It is structurally-sound and completely odourless and silent.

- It offers a low sludge generation and doesn’t compromise the quality of the treated effluent.

- It has low capital and operating cost.

- It is designed to meet the regulatory standards set by the Indian Ministry of Environment, Forest and Climate Change (MoEFCC) and Pollution Control Board (PCB) norms.

Daiki-Axis Japanese Packaged STPs (Johkasou) Applications and Uses

- Small Size Johkasou (1KLD – 5KLD) is well-suited for restaurants, public toilets, individual houses, etc.

- Mid-size Johkasou (10KLD – 50KLD) is suitable for hospitals, office complex, apartments, among others.

- Large-size Johkasou (50-300+ KLD) is ideal for commercial purposes, industries, townships, and more.